Machine CenterMachine Center

Wire-cut EDM

Die-sinker EDM

High - speed Small- hole Drilling EDM

Precision Metal 3D Printer

High-speed Milling Center

GL30

V-LINE® /Injection Molding Machine/for High Value-Added Products

V-LINE®'s global standard model contributes to high value-added molding in extensive fields, including precision, electronics, optics and medical equipments.

Main Features

Excellent Plasticization & Injection Performance

Equipped with a highly stable and highly reliable plasticization and injection unit realized by Sodick's original V-LINE® which contributes to accurate and highly repeatable resin injection, and a hydraulic accumulator mechanism that enables high speed injection with dynamic responsiveness at a high level.

Original Mold Open/Close & Clamping Mechanism

Adopts both a mold open/close mechanism which realizes accurate position control by an elect ronic system, and a mold clamping mechanism that reproduces an accurate mold clamping force by a hydraul ic sys tem. Equ ipped wi th a direct pres sure mold clamping system which utilizes the merits of the electro-hydraulic hybrid system to the utmost.

Total Servo Drive

Further improved energy saving performance by the use of an electric servo motor for the hydraulic pump drive, in addition to the electric servo motor drive for the mold open/ close mechanism and ejection mechanism.

Product Specifications

| Technical Specifications | |

|---|---|

| GL30 | |

| Clamping system | Locking Direct Pressure |

| Max. clamping force (kN) | 294[392] |

| Tie bar distance W×L (mm) | 310 x 310 |

| Platen Dimensions W×L (mm) | 440 x 440 |

| Open daylight (Min. mold thickness + Max. stroke) (mm) | 550 |

| Min. mold thickness/Max. mold thickness (mm) | 150/360 |

| Plasticization and Injection System | Screw Pre-plasticizing |

| Screw diameter (mm) | 14 | 18 | 22 |

| Plunger diameter (mm) | 12 | 16 | 22 |

| Max. injection pressure (MPa) | 288 | 262 | 260 |

| Theoretical injection volume (cm3) | 4.5 | 14 | 27 |

| Injection rate (cm3/s) | 57 | 101 | 190 |

| Max. injection speed (mm/s) | 500 |

| Plasticating capacity (kg/h) | 4 | 7 | 14 |

| Machine size L×W×H (mm) | 3150 x 1030 x 1679 |

| Machine weight (kg) | 2000 |

| Mold Clamping Force Classification | 20-99 |

| Drive system | Electric Hybrid |

GL60

V-LINE® /Injection Molding Machine/for High Value-Added Products

V-LINE®'s global standard model contributes to high value-added molding in extensive fields, including precision, electronics, optics and medical equipments.

Main Features

Excellent Plasticization & Injection Performance

Equipped with a highly stable and highly reliable plasticization and injection unit realized by Sodick's original V-LINE® which contributes to accurate and highly repeatable resin injection, and a hydraulic accumulator mechanism that enables high speed injection with dynamic responsiveness at a high level.

Original Mold Open/Close & Clamping Mechanism

Adopts both a mold open/close mechanism which realizes accurate position control by an elect ronic system, and a mold clamping mechanism that reproduces an accurate mold clamping force by a hydraul ic sys tem. Equ ipped wi th a direct pres sure mold clamping system which utilizes the merits of the electro-hydraulic hybrid system to the utmost.

Total Servo Drive

Further improved energy saving performance by the use of an electric servo motor for the hydraulic pump drive, in addition to the electric servo motor drive for the mold open/ close mechanism and ejection mechanism.

Product Specifications

| Technical Specifications | |

|---|---|

| GL60 | |

| Clamping system | Locking Direct Pressure |

| Max. clamping force (kN) | 588 |

| Tie bar distance W×L (mm) | 360 x 320 |

| Platen Dimensions W×L (mm) | 520 x 460 |

| Open daylight (Min. mold thickness + Max. stroke) (mm) | 650 |

| Min. mold thickness/Max. mold thickness (mm) | 200/390 |

| Plasticization and Injection System | Screw Pre-plasticizing |

| Screw diameter (mm) | 22 | 25 | 28 |

| Plunger diameter (mm) | 22 | 25 | 28 |

| Max. injection pressure (MPa) | 260 | 240 |

| Theoretical injection volume (cm3) | 27 | 49 | 83 |

| Injection rate (cm3/s) | 190 | 245 | 308 |

| Max. injection speed (mm/s) | 500 |

| Plasticating capacity (kg/h) | 10.5 | 20 | 30 |

| Machine size L×W×H (mm) | 3685 x 1094 x 1679 |

| Machine weight (kg) | 2800 |

| Mold Clamping Force Classification | 20-99 |

| Drive system | Electric Hybrid |

GL100

V-LINE® /Injection Molding Machine/for High Value-Added Products

V-LINE®'s global standard model contributes to high value-added molding in extensive fields, including precision, electronics, optics and medical equipments.

Main Features

Excellent Plasticization & Injection Performance

Equipped with a highly stable and highly reliable plasticization and injection unit realized by Sodick's original V-LINE® which contributes to accurate and highly repeatable resin injection, and a hydraulic accumulator mechanism that enables high speed injection with dynamic responsiveness at a high level.

Original Mold Open/Close & Clamping Mechanism

Adopts both a mold open/close mechanism which realizes accurate position control by an elect ronic system, and a mold clamping mechanism that reproduces an accurate mold clamping force by a hydraul ic sys tem. Equ ipped wi th a direct pres sure mold clamping system which utilizes the merits of the electro-hydraulic hybrid system to the utmost.

Total Servo Drive

Further improved energy saving performance by the use of an electric servo motor for the hydraulic pump drive, in addition to the electric servo motor drive for the mold open/ close mechanism and ejection mechanism.

Product Specifications

| Technical Specifications | |

|---|---|

| GL100 | |

| Clamping system | Locking Direct Pressure |

| Max. clamping force (kN) | 980 |

| Tie bar distance W×L (mm) | 460 x 420 |

| Platen Dimensions W×L (mm) | 640 x 610 |

| Open daylight (Min. mold thickness + Max. stroke) (mm) | 800 |

| Min. mold thickness/Max. mold thickness (mm) | 2250/550 |

| Plasticization and Injection System | Screw Pre-plasticizing |

| Screw diameter (mm) | 28 | 32 | 40 |

| Plunger diameter (mm) | 28 | 32 | 40 |

| Max. injection pressure (MPa) | 240 | 220 | 210 |

| Theoretical injection volume (cm3) | 83 | 108 | 251 |

| Injection rate (cm3/s) | 308 | 322 | 377 |

| Max. injection speed (mm/s) | 500 | 400 | 300 |

| Plasticating capacity (kg/h) | 30 | 40 | 44 |

| Machine size L×W×H (mm) | 4030 x 1196 x 1792 |

| Machine weight (kg) | 3300 |

| Mold Clamping Force Classification | 100-199 |

| Drive system | Electric Hybrid |

GL150

V-LINE® /Injection Molding Machine/for High Value-Added Products

V-LINE®'s global standard model contributes to high value-added molding in extensive fields, including precision, electronics, optics and medical equipments.

Main Features

Excellent Plasticization & Injection Performance

Equipped with a highly stable and highly reliable plasticization and injection unit realized by Sodick's original V-LINE® which contributes to accurate and highly repeatable resin injection, and a hydraulic accumulator mechanism that enables high speed injection with dynamic responsiveness at a high level.

Original Mold Open/Close & Clamping Mechanism

Adopts both a mold open/close mechanism which realizes accurate position control by an elect ronic system, and a mold clamping mechanism that reproduces an accurate mold clamping force by a hydraul ic sys tem. Equ ipped wi th a direct pres sure mold clamping system which utilizes the merits of the electro-hydraulic hybrid system to the utmost.

Total Servo Drive

Further improved energy saving performance by the use of an electric servo motor for the hydraulic pump drive, in addition to the electric servo motor drive for the mold open/ close mechanism and ejection mechanism.

Product Specifications

| Technical Specifications | |

|---|---|

| GL150 | |

| Clamping system | Locking Direct Pressure |

| Max. clamping force (kN) | 1472 |

| Tie bar distance W×L (mm) | 560 x 520 |

| Platen Dimensions W×L (mm) | 720 x 680 |

| Open daylight (Min. mold thickness + Max. stroke) (mm) | 900 |

| Min. mold thickness/Max. mold thickness (mm) | 250/600 |

| Plasticization and Injection System | Screw Pre-plasticizing |

| Screw diameter (mm) | 28 | 32 | 40 |

| Plunger diameter (mm) | 28 | 32 | 40 |

| Max. injection pressure (MPa) | 240 | 220 | 210 |

| Theoretical injection volume (cm3) | 83 | 108 | 251 |

| Injection rate (cm3/s) | 308 | 322 | 377 |

| Max. injection speed (mm/s) | 500 | 400 | 300 |

| Plasticating capacity (kg/h) | 30 | 40 | 44 |

| Machine size L×W×H (mm) | 4400 x 1378 x 1878 |

| Machine weight (kg) | 5100 |

| Mold Clamping Force Classification | 100-199 |

| Drive system | Electric Hybrid |

GL200

V-LINE® /Injection Molding Machine/for High Value-Added Products

V-LINE®'s global standard model contributes to high value-added molding in extensive fields, including precision, electronics, optics and medical equipments.

Main Features

Excellent Plasticization & Injection Performance

Equipped with a highly stable and highly reliable plasticization and injection unit realized by Sodick's original V-LINE® which contributes to accurate and highly repeatable resin injection, and a hydraulic accumulator mechanism that enables high speed injection with dynamic responsiveness at a high level.

Original Mold Open/Close & Clamping Mechanism

Adopts both a mold open/close mechanism which realizes accurate position control by an elect ronic system, and a mold clamping mechanism that reproduces an accurate mold clamping force by a hydraul ic sys tem. Equ ipped wi th a direct pres sure mold clamping system which utilizes the merits of the electro-hydraulic hybrid system to the utmost.

Total Servo Drive

Further improved energy saving performance by the use of an electric servo motor for the hydraulic pump drive, in addition to the electric servo motor drive for the mold open/ close mechanism and ejection mechanism.

Product Specifications

| Technical Specifications | |

|---|---|

| GL200 | |

| Clamping system | Locking Direct Pressure |

| Max. clamping force (kN) | 1960 |

| Tie bar distance W×L (mm) | 560 x 560 |

| Platen Dimensions W×L (mm) | 680 x 680 |

| Open daylight (Min. mold thickness + Max. stroke) (mm) | 950 |

| Min. mold thickness/Max. mold thickness (mm) | 300/650 |

| Plasticization and Injection System | Screw Pre-plasticizing |

| Screw diameter (mm) | 28 | 32 | 40 |

| Plunger diameter (mm) | 28 | 32 | 40 |

| Max. injection pressure (MPa) | 240 | 220 | 210 |

| Theoretical injection volume (cm3) | 83 | 108 | 251 |

| Injection rate (cm3/s) | 308 | 322 | 377 |

| Max. injection speed (mm/s) | 500 | 400 | 300 |

| Plasticating capacity (kg/h) | 30 | 40 | 44 |

| Machine size L×W×H (mm) | 4505 x 1360 x 1990 |

| Machine weight (kg) | 5900 |

| Mold Clamping Force Classification | 200-499 |

| Drive system | Electric Hybrid |

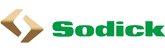

MS50

eV-LINE /Electric Injection Molding Machine

Based on high accuracy and stable molding by V-LINE®, Developed

Main Features

Electric V-LINE®

The injection and plasticizing apparatus using the V-LINE® system, with characteristics that ensure precise reproducibility, is now powered by a servomotor. Measurements and positioning data for the injection locations are controlled in a closed loop to improve the precision of positioning, achieving remarkably stable repetitions of the plasticizing, measuring, and injection cycle. The line of injection units with plungers of 22 mm and 28 mm in diameters include models that emphasize speed and models that emphasize pressure, allowing you to choose the unit that best suits the molded product type.

Electric clamping action

With the servo motor drive and adoption of the mold clamping device by the original toggle link mechanism shortened the mold opening and closing cycle. The movable platen is supported by a linear guide to improve the stability of the mold orientation. The power design for these products significantly reduces power usage while contributing to quieter operation.

Operation panel focused on intuition

Offering selector type switches, the control panel has been developed especially for the MS50. The ability to move the switches in the same direction in which you want each unit to move results in a more intuitive operating experience and helps simplify molding operations

Click link :: https://www.sodick.co.jp/special/ms_series/index_en.html

Product Specifications

| Technical Specifications | |

|---|---|

| MS50 | |

| Clamping system | Double Toggle |

| Max. clamping force (kN) | 490 |

| Tie bar distance W×L (mm) | 360 x 360 |

| Platen Dimensions W×L (mm) | 500 x 500 |

| Open daylight (Min. mold thickness + Max. stroke) (mm) | 600 |

| Min. mold thickness/Max. mold thickness (mm) | 150 / 350 |

| Plasticization and Injection System | Screw Pre-plasticizing |

| Screw diameter (mm) | 22 | 25 | 28 | 28 |

| Plunger diameter (mm) | 22 | 22 | 28 | 28 |

| Max. injection pressure (MPa) | 220 | 285 | 175 | 235 |

| Theoretical injection volume (cm3) | 53.2 | 98.5 |

| Injection rate (cm3/s) | 171 | 133 | 216 | 154 |

| Max. injection speed (mm/s) | 450 | 350 | 350 | 250 |

| Plasticating capacity (kg/h) | 14 | 9 | 20 | 13 | 35 | 24 | 35 | 24 |

| Machine size L×W×H (mm) | 3725 x 1155 x 1970.5 |

| Machine weight (kg) | 3000 |

| Mold Clamping Force Classification | 20-99 |

| Drive system | electric |

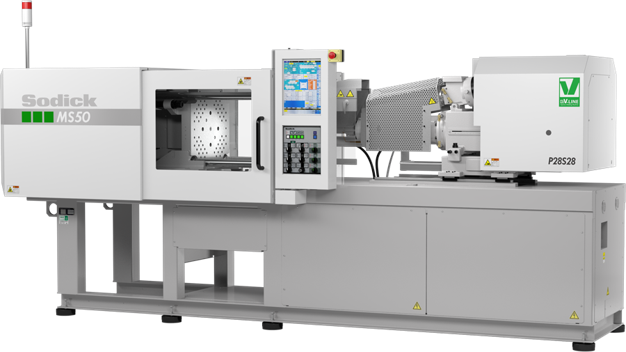

MS100

eV-LINE /Electric Injection Molding Machine

Based on high accuracy and stable molding by V-LINE®, Developed

Main Features

Electric V-LINE®

The injection and plasticizing apparatus using the V-LINE® system, with characteristics that ensure precise reproducibility, is now powered by a servomotor. Measurements and positioning data for the injection locations are controlled in a closed loop to improve the precision of positioning, achieving remarkably stable repetitions of the plasticizing, measuring, and injection cycle. The line of injection units with plungers of 22 mm and 28 mm in diameters include models that emphasize speed and models that emphasize pressure, allowing you to choose the unit that best suits the molded product type.

Electric clamping action

With the servo motor drive and adoption of the mold clamping device by the original toggle link mechanism shortened the mold opening and closing cycle. The movable platen is supported by a linear guide to improve the stability of the mold orientation. The power design for these products significantly reduces power usage while contributing to quieter operation.

Operation panel focused on intuition

Offering selector type switches, the control panel has been developed especially for the MS50. The ability to move the switches in the same direction in which you want each unit to move results in a more intuitive operating experience and helps simplify molding operations

Click link :: https://www.sodick.co.jp/special/ms_series/index_en.html

Product Specifications

| Technical Specifications | |

|---|---|

| MS100 | |

| Clamping system | Double Toggle |

| Max. clamping force (kN) | 980 |

| Tie bar distance W×L (mm) | 460 x 420 |

| Platen Dimensions W×L (mm) | 640 x 610 |

| Open daylight (Min. mold thickness + Max. stroke) (mm) | 800 |

| Min. mold thickness/Max. mold thickness (mm) | 200/450 |

| Plasticization and Injection System | Screw Pre-plasticizing |

| Screw diameter (mm) | 228 | 32 | 40 | 40 |

| Plunger diameter (mm) | 28 | 40 |

| Max. injection pressure (MPa) | 215 | 285 | 160 | 215 |

| Theoretical injection volume (cm3) | 98.5 | 251.3 |

| Injection rate (cm3/s) | 246 | 185 | 339 | 251 |

| Max. injection speed (mm/s) | 400 | 300 | 270 | 200 |

| Plasticating capacity (kg/h) | 35 | 24 | 45 | 30 | 85 | 60 | 85 | 60 |

| Machine size L×W×H (mm) | 4090 x 1215 x 2084 |

| Machine weight (kg) | 4600 |

| Mold Clamping Force Classification | 100-199 |

| Drive system | electric |

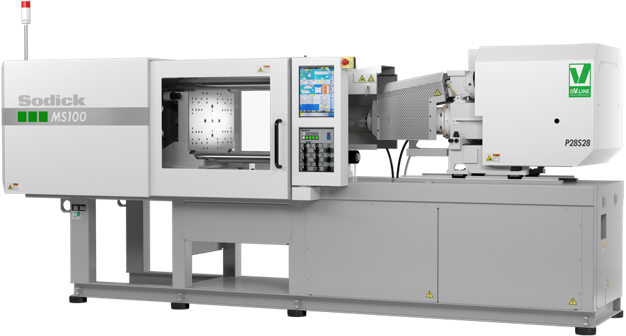

MS200

eV-LINE /Electric Injection Molding Machine

Based on high accuracy and stable molding by V-LINE®, Developed

Main Features

Electric V-LINE®

The injection and plasticizing apparatus using the V-LINE® system, with characteristics that ensure precise reproducibility, is now powered by a servomotor. Measurements and positioning data for the injection locations are controlled in a closed loop to improve the precision of positioning, achieving remarkably stable repetitions of the plasticizing, measuring, and injection cycle. The line of injection units with plungers of 22 mm and 28 mm in diameters include models that emphasize speed and models that emphasize pressure, allowing you to choose the unit that best suits the molded product type.

Electric clamping action

With the servo motor drive and adoption of the mold clamping device by the original toggle link mechanism shortened the mold opening and closing cycle. The movable platen is supported by a linear guide to improve the stability of the mold orientation. The power design for these products significantly reduces power usage while contributing to quieter operation.

Operation panel focused on intuition

Offering selector type switches, the control panel has been developed especially for the MS50. The ability to move the switches in the same direction in which you want each unit to move results in a more intuitive operating experience and helps simplify molding operations

Click link :: https://www.sodick.co.jp/special/ms_series/index_en.html

Product Specifications

| Technical Specifications | |

|---|---|

| MS200 | |

| Clamping system | Double Toggle |

| Max. clamping force (kN) | 1960 |

| Tie bar distance W×L (mm) | 560 x 560 |

| Platen Dimensions W×L (mm) | 720 x 720 |

| Open daylight (Min. mold thickness + Max. stroke) (mm) | 1000 |

| Min. mold thickness/Max. mold thickness (mm) | 250 / 550 |

| Plasticization and Injection System | Screw Pre-plasticizing |

| Screw diameter (mm) | 40 | 40 | 50 | 50 |

| Plunger diameter (mm) | 40 | 40 | 50 |

| Max. injection pressure (MPa) | 200 | 275 | 200 |

| Theoretical injection volume (cm3) | 251.3 | 392.7 |

| Injection rate (cm3/s) | 377 | 251 | 393 |

| Max. injection speed (mm/s) | 300 | 200 | 200 |

| Plasticating capacity (kg/h) | 85 | 60 | 100 | 100 |

| Machine size L×W×H (mm) | 5150 x 1445 x 2307 |

| Machine weight (kg) | 8400 |

| Mold Clamping Force Classification | 200-499 |

| Drive system | electric |