Die-sinker EDMDie-sinker EDM

Wire-cut EDM

High - speed Small- hole Drilling EDM

Precision Metal 3D Printer

High-speed Milling Center

Injection Machine

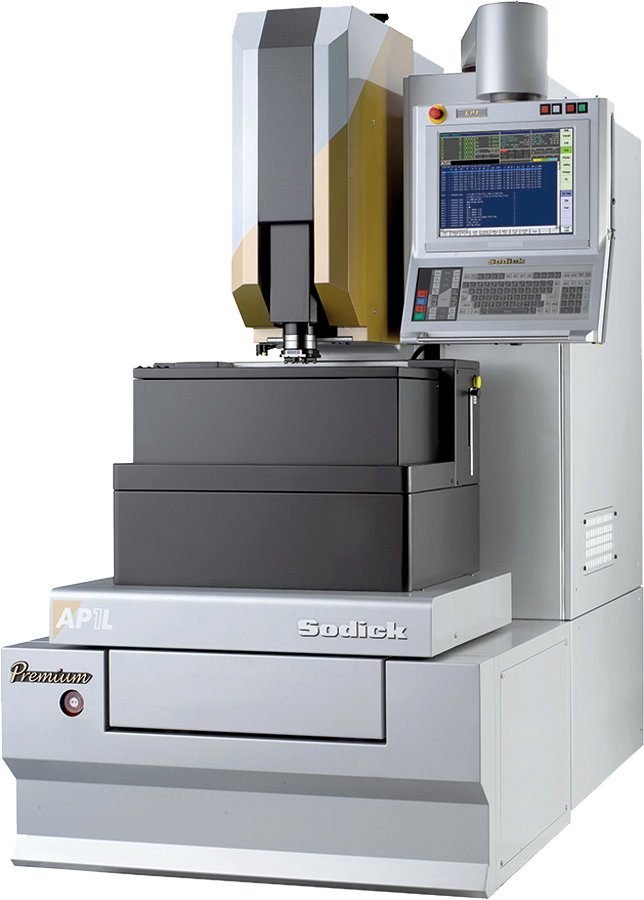

AP1L

Premium High End EDM Machine

Responding to the need for a higher level of machining accuracy, Sodick's AP1L Premium offers solutions to ultra precision machining requirements based on achieved superiority in mini and microscopic machining. production is improved through advanced functions for automation and labour saving operation. Revolutionary technology is needed for electrode dressing to support ultra precision high speed machining of hard and difficult materials in order to achieve manufacturing capability of mini and micro moulds.

Main Features

The screw-less drive, which uses a linear motor and linear scale, is the ideal drive method which maintains high-speed and high response performance semi-permanently. In addition, the AP1L employs the latest technology in highly rigid construction, small/precision head, and so on.

High-speed, high quality finishing “SVC” circuit

The “SVC” circuit increases the machining speed in finishing compared to our previous model, and supplies a uniform discharge pulse between the electrodes. The optimum surface roughness over the machining area is greatly improved, realizing a high quality pear-skin or mirror finish

Three-sided automated vertical slide machining tank

The three-sided automated vertical slide machining tank facilitates setup work for super-precision machining. It also enables an optimum cost to be configured when a robot is adopted for automation and labor saving.

product Specifications

| Technical Specifications | |

|---|---|

| X - Axis Travel (mm) | 200 |

| Y - Axis Travel (mm) | 120 |

| Z - Axis Travel (mm) | 200 |

| Work Table Size (mm) | 360 x 220 |

| Work Tank Size (mm) | 503 x 349 x 250 |

| Fluid Level (min ~ max) (mm) | 80 ~ 200 |

| Work Tank Capacity (Liters) | 120 |

| Max. workpiece weight (kg) | 250 |

| Machine Dimensions (W x D x H, mm, Incl. power supply and dielectric tank) |

1355 x 1895 x 2030 |

| Machine weight (kg) | 3100 |

| Standard Features |

|---|

| Linear Motor (X/Y/Z axis) |

| Linear scale (X/Y/Z axis) |

| Ceramic components |

| Linear motor cooling unit |

| SVC circuit |

| "SGF" Nano-Wear Discharge Unit |

| Q³vic EDM |

AP3L

Premium High End EDM Machine

Ultrahigh Rigidity Double-Column structure and Linear Motor drive Employing a New Power supply unit Enhances productivity in ultrafine and Ultraprecision Machining.

Direct-drive & Unique structure

The AP3L employs linear motors in achieving direct-drive with high speed and fast dynamic responsiveness that will not diminish over time. The unique gantry construction provides a low center-of-gravity which minimizes mechanical displacement caused by workpiece weight. The new small head also works to improve accuracy.

"Arc-less" machining

The new "Arc-less" EDM machining system is a new standard feature which greatly improves machining speed and accuracy, and also minimizes human errors In addition, the Super-SVC circuit reduces surface roughness variation, and makes high quality “pear-skin” or mirror-finish surface possible with ease.

Ecology & Energy saving

AP3L is environment friendly, recognizing the importance of energy conservation and material waste reduction in its design. Sodick has gone back to the drawing board to re-think and re-examine all machine components, and worked to accomplish significant reduction in the number of parts used for machine construction

product Specifications

| Technical Specifications | |

|---|---|

| X - Axis Travel (mm) | 300 |

| Y - Axis Travel (mm) | 250 |

| Z - Axis Travel (mm) | 250 |

| Work Table Size (mm) | 500 x 350 |

| Work Tank Size (mm) | 760 x 538 x 260 |

| Fluid Level (min ~ max) (mm) | 80 ~ 210 |

| Work Tank Capacity (Liters) | 150 |

| Max. workpiece weight (kg) | 200 |

| Machine Dimensions (W x D x H, mm, Incl. power supply and dielectric tank) |

1555 x 1945 x 1990 |

| Machine weight (kg) | 4000 |

| Standard Features |

|---|

| Linear Motor (X/Y/Z axis) |

| Linear scale (X/Y/Z axis) |

| Ceramic components |

| Linear motor cooling unit |

| SVC circuit |

| "SGF" Nano-Wear Discharge Unit |

| Q³vic EDM |

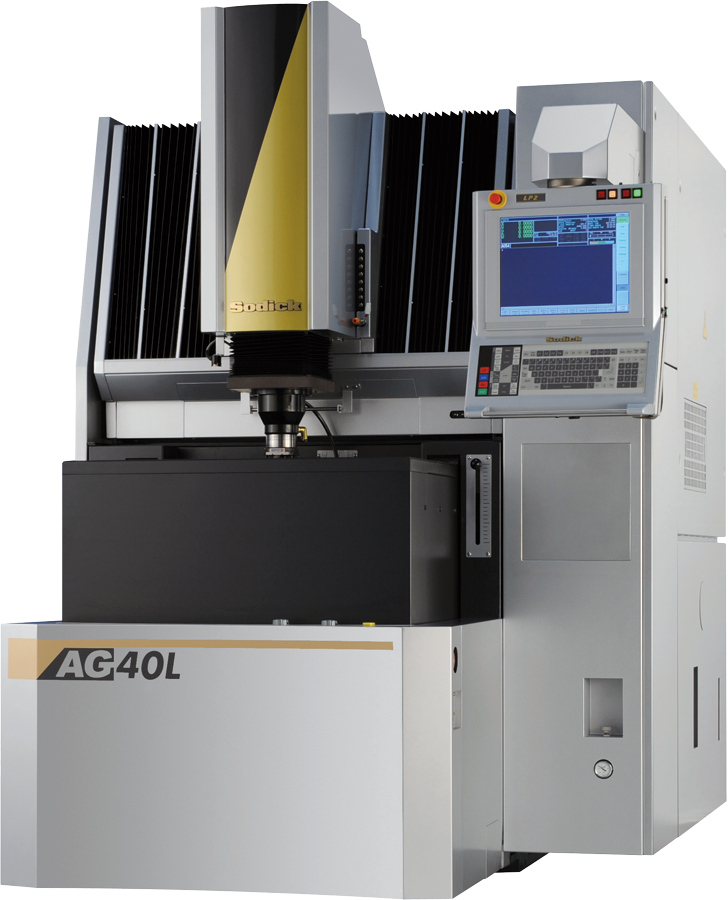

AG40L/AG60L

Premium High End EDM Machine

The AG40L/AG60L Sinker EDM features Sodick’s Linear MotorTechnology Sodick’s best selling Die sinker EDM range “AG series” ensures that machining in half the time has become an economically efficient reality The series features linear drive technology and simplified control mechanisms, which provide a direct link between the drive and the control. This ensures the fastest possible servo-response and optimal spark gaps at all times

Linear Motor Drive System

Linear motor drive system is the most ideal mechanism which semi-permanently sustains high-speed axis-movements and instantaneous response.

New "LP2" Controller

The 5th generation electrical discharge technology "LP2" has adopted the "Perfect Active Control," enabling simultaneous control of high-speed electrical discharge and axis- movements by using serial communication technology of 1Gbit/sec.

Arc-less & High Quality Surface Finish

The new "Arc-less" electrical discharge system features further improved in machining performance, and ensures great reduction in machining time. Equipped with "SVC" circuit as standard, high-quality surface finishing, satin surface, and mirror surface can be achieved with great ease.

product Specifications

| Technical Specifications | ||

|---|---|---|

| AG40L | AG60L | |

| X - Axis Travel (mm) | 400 | 600 |

| Y - Axis Travel (mm) | 300 | 420 |

| Z - Axis Travel (mm) | 270 | 370 |

| Work Table Size (mm) | 600 x 400 | 750 x 550 |

| Work Tank Size (mm) | 750 x 620 x 350 | 950 x 740 x 450 |

| Fluid Level (min ~ max) (mm) | 100 ~ 300 | 150 ~ 400 |

| Dielectric fluid Tank Capacity (Liters) |

285 | 465 |

| Max. workpiece weight (kg) | 550 | 1500 |

| Machine Dimensions (W x D x H, mm, Incl. power supply and dielectric tank) |

1550 x 2440 x 2330 | 1852 x 2825 x 2570 |

| Machine weight (kg) | 4000 | 5350 |

| Standard Features |

|---|

| Linear Motor (X/Y/Z axis) |

| Absolute Linear scale (X/Y/Z axis) |

| Ceramic components |

| Linear motor cooling unit |

| SVC circuit |

| "SGF2" Nano-Wear Discharge Unit |

| TMM3 generator |

AG80L/AG100L

Linear Motor Drive High speed & high precision Die-sinker EDM

The AG80L/AG100L Sinker EDM features Sodick’s Linear MotorTechnology Sodick’s best selling Die sinker EDM range “AG series” ensures that machining in half the time has become an economically efficient reality The series features linear drive technology and simplified control mechanisms, which provide a direct link between the drive and the control. This ensures the fastest possible servo-response and optimal spark gaps at all times.

Main Features

Linear Motor Drive System

Linear motor drive system is the most ideal mechanism which semi-permanently sustains high-speed axis-movements and instantaneous response.

New "LP2" Controller

The 5th generation electrical discharge technology "LP2" has adopted the "Perfect Active Control," enabling simultaneous control of high-speed electrical discharge and axis- movements by using serial communication technology of 1Gbit/sec.

Arc-less & High Quality Surface Finish

The new "Arc-less" electrical discharge system features further improved in machining performance, and ensures great reduction in machining time. Equipped with "SVC" circuit as standard, high-quality surface finishing, satin surface, and mirror surface can be achieved with great ease.

product Specifications

| Technical Specifications | ||

|---|---|---|

| AG80L | AG100L | |

| X - Axis Travel (mm) | 850 | 1200 |

| Y - Axis Travel (mm) | 520 | 650 |

| Z - Axis Travel (mm) | 420 | 500 |

| Work Table Size (mm) | 1100 x 700 | 1600 x 1000 |

| Work Tank Size (mm) | 1400x950x500 | 2100x1250x650 |

| Fluid Level (min ~ max) (mm) | 200 ~ 450 | 325 ~ 600 |

| Dielectric fluid Tank Capacity (Liters) |

845 | 2770 |

| Max. workpiece weight (kg) | 3000 | 5000 |

| Machine Dimensions (W x D x H, mm, Incl. power supply and dielectric tank) |

2060 x 3130 x 2900 | 3820 x 4200 x 3340 |

| Machine weight (kg) | 9400 | 12500 |

| Standard Features |

|---|

| Linear Motor (X/Y/Z axis) |

| Absolute Linear scale (X/Y/Z axis) |

| Ceramic components |

| Linear motor cooling unit |

| SVC circuit |

| "SGF2" Nano-Wear Discharge Unit |

| TMM3 generator |

AD35L/AD55L

Linear Motor Drive Die-sinker EDM

High Speed and High Performance 3 Axes Linear Motor Drive EDM The screw-less drive, which uses a linear motor and linear scale, is the ideal drive method which maintains high-speed and high response performance semi-permanently. In addition, the AD35L employs the latest technology in highly rigid construction.

Main Features

Screw-Less drive + highly rigid construction

The screw-less drive, which uses a linear motor and liner scale, is the ideal drive method which maintenance high-speed and high response performance semi-permanently. In addition, the AD Series employs the lasted technology in highly rigid construction.

New NC Unit with "TMM3" Discharge Power Supply

The AD Sieries features Sodick's latest "LN" NC unit equipped with the new "TMM3" discharge power supply, capable of high-speed, high precision and high-efficiency machining.It is equipped with "LN Professional", Automatic programming funtion, as standrad.

Arc-less & High Quality Surface Finish

The new "Arc-less" electrical discharge system features further improved in machining performance, and ensures great reduction in machining time. Equipped with "SVC" circuit as standard, high-quality surface finishing, satin surface, and mirror surface can be achieved with great ease.

product Specifications

| Technical Specifications | ||

|---|---|---|

| AD35l | AD55L | |

| X - Axis Travel (mm) | 350 | 600 |

| Y - Axis Travel (mm) | 250 | 400 |

| Z - Axis Travel (mm) | 270 | 400 |

| Work Table Size (mm) | 600 x 400 | 750 x 550 |

| Work Tank Size (mm) | 975 x 555 x 350 | 1200 x 800 x 500 |

| Fluid Level (min ~ max) (mm) | ||

| Dielectric fluid Tank Capacity (Liters) |

400 | 800 |

| Max. workpiece weight (kg) | 550 | 1000 |

| Machine Dimensions (W x D x H, mm, Incl. power supply and dielectric tank) |

1895 x 1955 x 2350 | 2335 x 2325 x 2725 |

| Machine weight (kg) | 3200 | 4570 |