Die-sinker EDMDie-sinker EDM

ซีรีส์ AL

ซีรีส์ AG

ซีรีส์ AQ

ซีรีส์ AD

ซีรีส์ AP

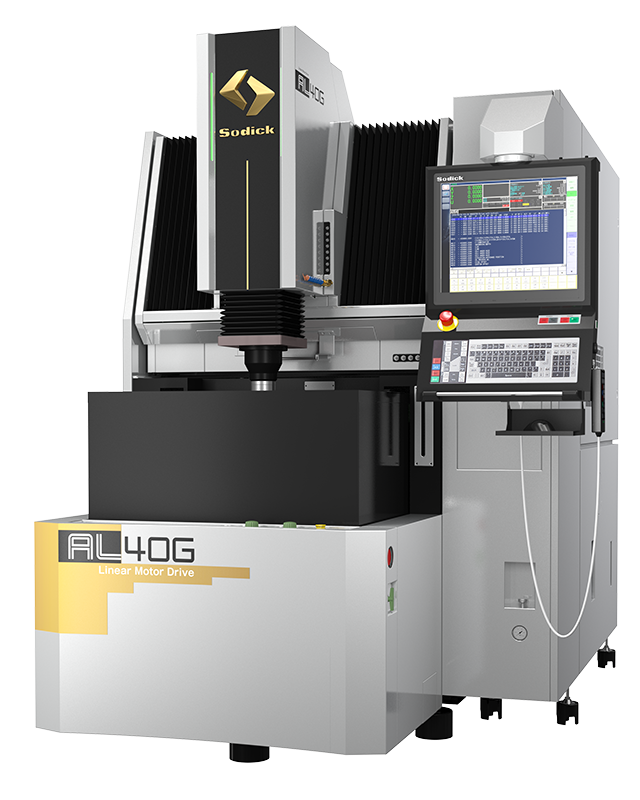

AL40G

ลิเนียร์มอเตอร์ไดรฟ์ /ความเร็วสูงและความแม่นยำสูง /Die-sinker EDM

รองรับแม่พิมพ์ที่มีความแม่นยำและการตัดเฉือนชิ้นส่วนด้วยมอเตอร์แนวราบและเทคโนโลยีการปล่อยไฟฟ้าล่าสุด

คุณสมบัติหลัก

ลิเนียร์มอเตอร์ไดรฟ์โครงสร้างแข็งสูง

"ซีรีส์ AL" ติดตั้งมอเตอร์เชิงเส้นตรงที่พัฒนาและผลิตขึ้นเองภายในบริษัท และแสดงให้เห็นถึงการตัดเฉือนที่มีความเร็วสูงและตอบสนองสูง เมื่อใช้ร่วมกับโครงสร้างเครื่องจักรที่มีความแข็งแกร่งสูง การใช้ฟังก์ชันการแก้ไขที่แม่นยำ "TH COM" จะช่วยลดปริมาณการระบายความร้อนลง 50% เมื่อเทียบกับซีรีส์ทั่วไป

"SP Power Supply" ที่พัฒนาขึ้นใหม่

ความเร็วในการสื่อสารและปริมาณงานได้รับการปรับปรุงใน "SP Power Supply" ที่พัฒนาขึ้นใหม่สำหรับ EDM แบบไดซิงเกอร์ ซึ่งเพิ่มความเร็วในการตอบสนองของการควบคุมมอเตอร์มากกว่าสองเท่า การใช้วงจร "TMM4" และ "BSN4" ใหม่ช่วยปรับปรุงคุณภาพและความเร็วของช่วงการตัดเฉือนการปล่อยไฟฟ้าโดยรวม

Arc-less 4 วงจร

การนำวงจรเทคโนโลยีควบคุมการจ่ายกระแสไฟ "Arc-less 4" มาใช้ช่วยปรับปรุงประสิทธิภาพของ EDM แบบได-ซิงเกอร์อย่างมาก เช่น ความเร็วที่เพิ่มขึ้น ลดการสึกหรอของอิเล็กโทรด และตระหนักถึงคุณภาพพื้นผิวการตัดเฉือนที่หลากหลายตั้งแต่พื้นผิวซาตินไปจนถึงพื้นผิวกระจก นอกจากนี้ยังติดตั้งที่ปรึกษาสภาพการตัดเฉือน AI "LN Pro AI"

ข้อมูลจำเพาะของผลิตภัณฑ์

| Machine Tool | |||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X - Axis Travel (mm) | 400 | ||||||||||||||||||||||||||||||||||||||

| Y - Axis Travel (mm) | 300 | ||||||||||||||||||||||||||||||||||||||

| Z - Axis Travel (mm) | 270 | ||||||||||||||||||||||||||||||||||||||

| Work Table Size (W x D) | 600 x 400 (Ceramic) | ||||||||||||||||||||||||||||||||||||||

| Work Tank Inner Dimensions (W x D x H) (mm) | 750 x 620 x 350 | ||||||||||||||||||||||||||||||||||||||

| Work Tank Fluid Level (Min to Max) (mm) | 100 ~ 300 | ||||||||||||||||||||||||||||||||||||||

| Work Tank Capacity 190 Liters X Axis Travel (Liters) |

190 | ||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||

| Max Weight of Electrode (kg) | 50 | ||||||||||||||||||||||||||||||||||||||

| Max Workpiece Weight (kg) | 550 | ||||||||||||||||||||||||||||||||||||||

| Distance Between Electrode and Table Top (mm*1) | 150 〜 420 | ||||||||||||||||||||||||||||||||||||||

| Distance from Floor to Table Top (mm) | 830 | ||||||||||||||||||||||||||||||||||||||

| Machine Tool Dimensions (W x D x H) (Includes a Power Supply and Dielectric Tank) |

1550 x 2440 x 2330 | ||||||||||||||||||||||||||||||||||||||

| Machine Tool Weight (Includes a Power Supply and Dielectric Tank) (kg) |

4000 | ||||||||||||||||||||||||||||||||||||||

| Air Pressure (MPa*2) | 0.65 | ||||||||||||||||||||||||||||||||||||||

| Air Flow (NL/min) | 100 | ||||||||||||||||||||||||||||||||||||||

| Total Power Input (mm) | 3-phase, 50/60 Hz, 10 kVA | ||||||||||||||||||||||||||||||||||||||

| *1 EROWA/TP specification

*2 If required air pressure is not met, Pressure Booster (Option) must be installed. |

|||||||||||||||||||||||||||||||||||||||

| Dielectric Tank | |

|---|---|

| Dielectric Fluid | EDM Oil |

| Dielectric Tank Capacity (Liters) | 285 |

| Required Amount (Liters) | 330 |

| Filtration | Replaceable Paper Filters |

| CNC Power Supply SP/SP-E | |

|---|---|

| Max. Machining Current | 40A |

| Discharging Power Supply Unit | Optimum Pulse Control [Arc-less 4, TMM 4,TPC 4, BSN 4, SVC] |

| Power Requirement | AC200 V, 50/60 Hz |

| NC Unit | Multitask OS, K - SMC-LINK Method (M4 - LINK) |

| User’s Memory Capacity | Editing: 100,000 Blocks Saving: 30 MB |

| Memory Device | SSD Card, Dedicated USB Memory |

| Input Format | Dedicated USB Memory, Multi Touch Panel, Keyboard, LAN |

| Display Type | 19-inch TFT-LCD |

| Character | Set Kanji (JIS Level 1 Kanji Characters), Alphabetic Characters, Numeric Characters, etc. |

| Keyboard | Standard 101 Keyboard, Function Key |

| Positioning Command | Incremental and Absolute |

| Max. Input Command | ±999999.999/±99999.9999/±9999.99999 (switchable) |

| Machining Conditions Storage Capacity | 1000 Conditions (C000 to C999) |

| Offset Setting Storage Capacity | 1000 Conditions (H000 to H999) |

| Program Sequence Number Assignment | N000000000 to N999999999 |

| Number of Coordinates | 60 |

| Simultaneous Control Axes | Max. 4 Axes (SP-E: 6 Axis Specification/8 Axis Specification) |

| Min. Input Command | 0.001μm |

| Min. Drive Unit | 0.01μm |

| AJC Speed | XY Axis : Max. 10 m/min, Z Axis : Max. 36 m/min |

| Max. Feed Rate XYZ Axis | 6 m/min |

| Position Detection Mechanism | Full - closed Loop (Linear Scale) |

| Drive Mechanism | Linear Motor |

| Compensations | Pitch Error Correction, Plane Pitch Error Correction, Torque Correction for Each Axis |

| Graphics | XY/ YZ/ ZX Plane, Graphics Drawing During Machining, Background Graphics Drawing, LORAN Shape Drawings, Discharge Graphs, etc. |

| IoT | Compatible to S-VIEWER (Compatible to MT-CONNECT : Option) |

| Maintenance | AI Maintenance |

AL60G

ลิเนียร์มอเตอร์ไดรฟ์ /ความเร็วสูงและความแม่นยำสูง /Die-sinker EDM

รองรับแม่พิมพ์ที่มีความแม่นยำและการตัดเฉือนชิ้นส่วนด้วยมอเตอร์แนวราบและเทคโนโลยีการปล่อยไฟฟ้าล่าสุด

คุณสมบัติหลัก

ลิเนียร์มอเตอร์ไดรฟ์โครงสร้างแข็งสูง

"ซีรีส์ AL" ติดตั้งมอเตอร์เชิงเส้นตรงที่พัฒนาและผลิตขึ้นเองภายในบริษัท และแสดงให้เห็นถึงการตัดเฉือนที่มีความเร็วสูงและตอบสนองสูง เมื่อใช้ร่วมกับโครงสร้างเครื่องจักรที่มีความแข็งแกร่งสูง การใช้ฟังก์ชันการแก้ไขที่แม่นยำ "TH COM" จะช่วยลดปริมาณการระบายความร้อนลง 50% เมื่อเทียบกับรุ่นทั่วไป

"SP Power Supply" ที่พัฒนาขึ้นใหม่

ความเร็วในการสื่อสารและปริมาณงานได้รับการปรับปรุงใน "SP Power Supply" ที่พัฒนาขึ้นใหม่สำหรับ EDM แบบไดซิงเกอร์ ซึ่งเพิ่มความเร็วในการตอบสนองของการควบคุมมอเตอร์มากกว่าสองเท่า การใช้วงจร "TMM4" และ "BSN4" ใหม่ช่วยปรับปรุงคุณภาพและความเร็วของช่วงการตัดเฉือนการปล่อยไฟฟ้าโดยรวม

Arc-less 4 วงจร

การนำวงจรเทคโนโลยีควบคุมการจ่ายกระแสไฟ "Arc-less 4" มาใช้ช่วยปรับปรุงประสิทธิภาพของ EDM แบบได-ซิงเกอร์อย่างมาก เช่น ความเร็วที่เพิ่มขึ้น ลดการสึกหรอของอิเล็กโทรด และตระหนักถึงคุณภาพพื้นผิวการตัดเฉือนที่หลากหลายตั้งแต่พื้นผิวซาตินไปจนถึงพื้นผิวกระจก นอกจากนี้ยังติดตั้งที่ปรึกษาสภาพการตัดเฉือน AI "LN Pro AI"

ข้อมูลจำเพาะของผลิตภัณฑ์

| ข้อกำหนดทางเทคนิค | |||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X - Axis Travel (mm) | 600 | ||||||||||||||||||||||||||||||||||||||

| Y - Axis Travel (mm) | 420 | ||||||||||||||||||||||||||||||||||||||

| Z - Axis Travel (mm) | 370 | ||||||||||||||||||||||||||||||||||||||

| Work Table Size (W x D) | 750 x 550 (Ceramic) | ||||||||||||||||||||||||||||||||||||||

| Work Tank Inner Dimensions (W x D x H) (mm) | 950 x 740 x450 | ||||||||||||||||||||||||||||||||||||||

| Work Tank Fluid Level (Min to Max) (mm) | 150 ~ 400 | ||||||||||||||||||||||||||||||||||||||

| Work Tank Capacity 190 Liters X Axis Travel (Liters) |

330 | ||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||

| Max Weight of Electrode (kg) | 50 | ||||||||||||||||||||||||||||||||||||||

| Max Workpiece Weight (kg) | 1500 | ||||||||||||||||||||||||||||||||||||||

| Distance Between Electrode and Table Top (mm*1) | 200 〜 570 | ||||||||||||||||||||||||||||||||||||||

| Distance from Floor to Table Top (mm) | 850 | ||||||||||||||||||||||||||||||||||||||

| Machine Tool Dimensions (W x D x H) (Includes a Power Supply and Dielectric Tank) |

1740 x 2785 x 2570 | ||||||||||||||||||||||||||||||||||||||

| Machine Tool Weight (Includes a Power Supply and Dielectric Tank) (kg) |

5150 | ||||||||||||||||||||||||||||||||||||||

| Air Pressure (MPa*2) | 0.65 | ||||||||||||||||||||||||||||||||||||||

| Air Flow (NL/min) | 100 | ||||||||||||||||||||||||||||||||||||||

| Total Power Input (mm) | 3-phase, 50/60 Hz, 10 kVA | ||||||||||||||||||||||||||||||||||||||

| Dielectric Fluid | EDM Oil | ||||||||||||||||||||||||||||||||||||||

| Dielectric Tank Capacity (Liters) | 465 | ||||||||||||||||||||||||||||||||||||||

| Required Amount (Liters) | 560 | ||||||||||||||||||||||||||||||||||||||

| Filtration | Replaceable Paper Filters | ||||||||||||||||||||||||||||||||||||||

| Max. Machining Current | 40A | ||||||||||||||||||||||||||||||||||||||

| Discharging Power Supply Unit | Optimum Pulse Control [Arc-less 4, TMM 4,TPC 4, BSN 4, SVC] | ||||||||||||||||||||||||||||||||||||||

| Power Requirement | AC200 V, 50/60 Hz | ||||||||||||||||||||||||||||||||||||||

| NC Unit | Multitask OS, K - SMC-LINK Method (M4 - LINK) | ||||||||||||||||||||||||||||||||||||||

| User’s Memory Capacity | Editing: 100,000 Blocks Saving: 30 MB |

||||||||||||||||||||||||||||||||||||||

| Memory Device | SSD Card, Dedicated USB Memory | ||||||||||||||||||||||||||||||||||||||

| Input Format | Dedicated USB Memory, Multi Touch Panel, Keyboard, LAN |

||||||||||||||||||||||||||||||||||||||

| Display Type | 19-inch TFT-LCD | ||||||||||||||||||||||||||||||||||||||

| Character | Set Kanji (JIS Level 1 Kanji Characters), Alphabetic Characters, Numeric Characters, etc. |

||||||||||||||||||||||||||||||||||||||

| Keyboard | Standard 101 Keyboard, Function Key | ||||||||||||||||||||||||||||||||||||||

| Positioning Command | Incremental and Absolute | ||||||||||||||||||||||||||||||||||||||

| Max. Input Command | ±999999.999/±99999.9999/±9999.99999 (switchable) | ||||||||||||||||||||||||||||||||||||||

| Machining Conditions Storage Capacity | 1000 Conditions (C000 to C999) | ||||||||||||||||||||||||||||||||||||||

| Offset Setting Storage Capacity | 1000 Conditions (H000 to H999) | ||||||||||||||||||||||||||||||||||||||

| Program Sequence Number Assignment | N000000000 to N999999999 | ||||||||||||||||||||||||||||||||||||||

| Number of Coordinates | 60 | ||||||||||||||||||||||||||||||||||||||

| Simultaneous Control Axes | Max. 4 Axes (SP-E: 6 Axis Specification/8 Axis Specification) |

||||||||||||||||||||||||||||||||||||||

| Min. Input Command | 0.001μm | ||||||||||||||||||||||||||||||||||||||

| Min. Drive Unit | 0.01μm | ||||||||||||||||||||||||||||||||||||||

| AJC Speed | XY Axis : Max. 10 m/min, Z Axis : Max. 36 m/min | ||||||||||||||||||||||||||||||||||||||

| Max. Feed Rate XYZ Axis | 6 m/min | ||||||||||||||||||||||||||||||||||||||

| Position Detection Mechanism | Full - closed Loop (Linear Scale) | ||||||||||||||||||||||||||||||||||||||

| Drive Mechanism | Linear Motor | ||||||||||||||||||||||||||||||||||||||

| Compensations | Pitch Error Correction, Plane Pitch Error Correction, Torque Correction for Each Axis |

||||||||||||||||||||||||||||||||||||||

| Graphics | XY/ YZ/ ZX Plane, Graphics Drawing During Machining, Background Graphics Drawing, LORAN Shape Drawings, Discharge Graphs, etc. |

||||||||||||||||||||||||||||||||||||||

| IoT | Compatible to S-VIEWER (Compatible to MT-CONNECT : Option) | ||||||||||||||||||||||||||||||||||||||

| Maintenance | AI Maintenance | ||||||||||||||||||||||||||||||||||||||

| *1 EROWA/TP specification

*2 If required air pressure is not met, Pressure Booster (Option) must be installed. |

|||||||||||||||||||||||||||||||||||||||

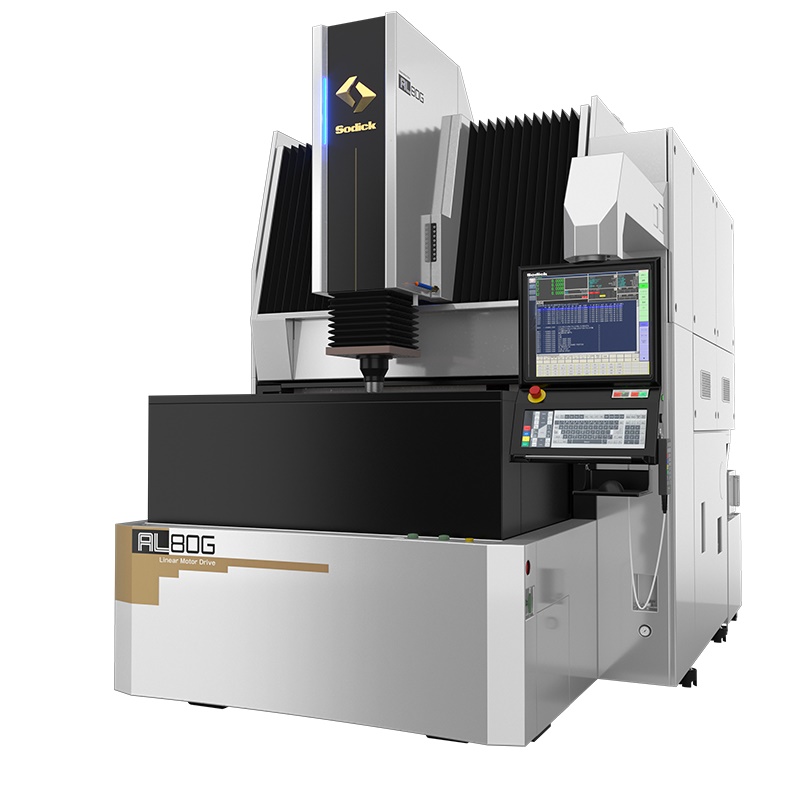

AL80G

Linear Motor Drive /High-speed & High-precision Die-sinker EDM

The AL80G, linear motor drive die-sinker EDM which incorporates Sodick’s new generation SP controller with the Smart Pulse generator is now available in the Sodick product range.

คุณสมบัติหลัก

The new model features Sodick’s advanced technologies and latest innovation to realise unrivalled machining performance.

ข้อมูลจำเพาะของผลิตภัณฑ์

| ข้อกำหนดทางเทคนิค | |

|---|---|

| X-/Y-/Z- axis stroke (mm) | 850 x 520 x 420 |

| Ceramic table dimensions (W x D, mm) | 1,100 x 700 |

| Worktank dimensions (W x D x H mm) | 1,400 x 950 x 500 |

| Dielectric fluid level (mm) | 150 ~ 450 |

| Max. workpiece weight (kg) | 3,000 |

| Max. electrode weight (kg) | 100 |

| Distance from table to chuck (mm) | 250 ~ 670 |

| Distance from floor to table top (mm) | 840 |

| Machine weight (kg) | 9,800 |

| Machine installation space (W x D mm) | 3,100 x 4,570 (excluding ATC unit) |

| Total power input | 3-phases, 50/60Hz, 17KvA |

| คุณสมบัติมาตรฐาน |

|---|

| 10-year guarantee on positioning accuracy |

| Linear Motor (X/Y/Z axis) |

| Absolute Linear scale (X/Y/Z axis) |

| Ceramic components |

| Sodick Motion Controller |

| Linear motor cooling unit |

| Dielectric fluid cooling unit |

| SVC circuit |

| “SGF4” Nano-Wear Discharge Unit |

| TMM4 |

| BSN4 finishing circuit |

| SP controller |

| 19" TFT colour screen |

| Intelligent Q³vic EDM |

| Remote controller |

| LN Professional AI software for optimum condition search |

| 3-side Rise and fall woank |

| Clamping chuck |

| LAN interface |

| USB port |

| Totalising hour metre |

| Work light |

| ตัวเลือก |

|---|

| C-axis SEC10 (20 rpm) |

| ATC Unit (6, 12, 16, 32-station) |

| SCF72P High-precision rotary head (2000 rpm) |

| 40A Booster |

| Table Down 50 mm (Factory option) |

| Oscilloscope |

| Active Power Restart (UPS) |

| Automation system |

| 8-axis simultaneous control SP-E (Factory option) |

| Custom Colour |

AG100L

Linear Motor Drive High Speed & High Precision Die-Sinker EDM

Best selling Die-sinker EDM which realizes high-speed and high-performance by screw-less drive and arc-less machining.

คุณสมบัติหลัก

Linear Motor Drive System

Linear motor drive system is the most ideal mechanism which semi-permanently sustains high-speed axis-movements and instantaneous response.

New Generator

The 5th generation electrical discharge technology "LP2" has adopted the "Perfect Active Control," enabling simultaneous control of high-speed electrical discharge and axis- movements by using serial communication technology of 1Gbit/sec.

Arc-less & High Quality Surface Finish

The new "Arc-less" electrical discharge system features further improved in machining performance, and ensures great reduction in machining time. Equipped with "SVC" circuit as standard, high-quality surface finishing, satin surface, and mirror surface can be achieved with great ease.

ข้อมูลจำเพาะของผลิตภัณฑ์

| ข้อกำหนดทางเทคนิค | ||

|---|---|---|

| X/Y/Z axis travel (mm) | 1200 x 650 x 500 | |

| Table dimensions (mm) | 1600 x 1000 | |

| Worktank dimensions (mm) | 2100 x 1250 x 650 | |

| Dielectric level (min ~ max, mm) | 325 ~ 600 | |

| Max. workpiece weight (kg) | 5000 | |

| Max. electrode weight (kg) | 100 | |

| Distance from floor to table top (mm) | 940 | |

| Machine tool dimensions (W x D x H, mm,) | 3820 x 4200 x 3340 (Incl. power supply and dielectric tank) |

|

| Step resolution (mm) | 0.0001 | |

| Machine weight (kg) | 12500 | |

| Controlled axis | 4 | |

| Air pressure | 0.65 (Automatic Clamping chuck, MPa) |

|

| External dimensions Main- (W x D x H, mm) Sub- |

2520 x 900 x 2330 900 x 2650 x 1250 |

|

| Empty weight (kg) | 650 (main) + 450 (sub) | |

| Dielectric fluid | Oil | |

| Capacity (l) | 2770 | |

| Filtration method | 6 replaceable paper filters (MF-2400) | |

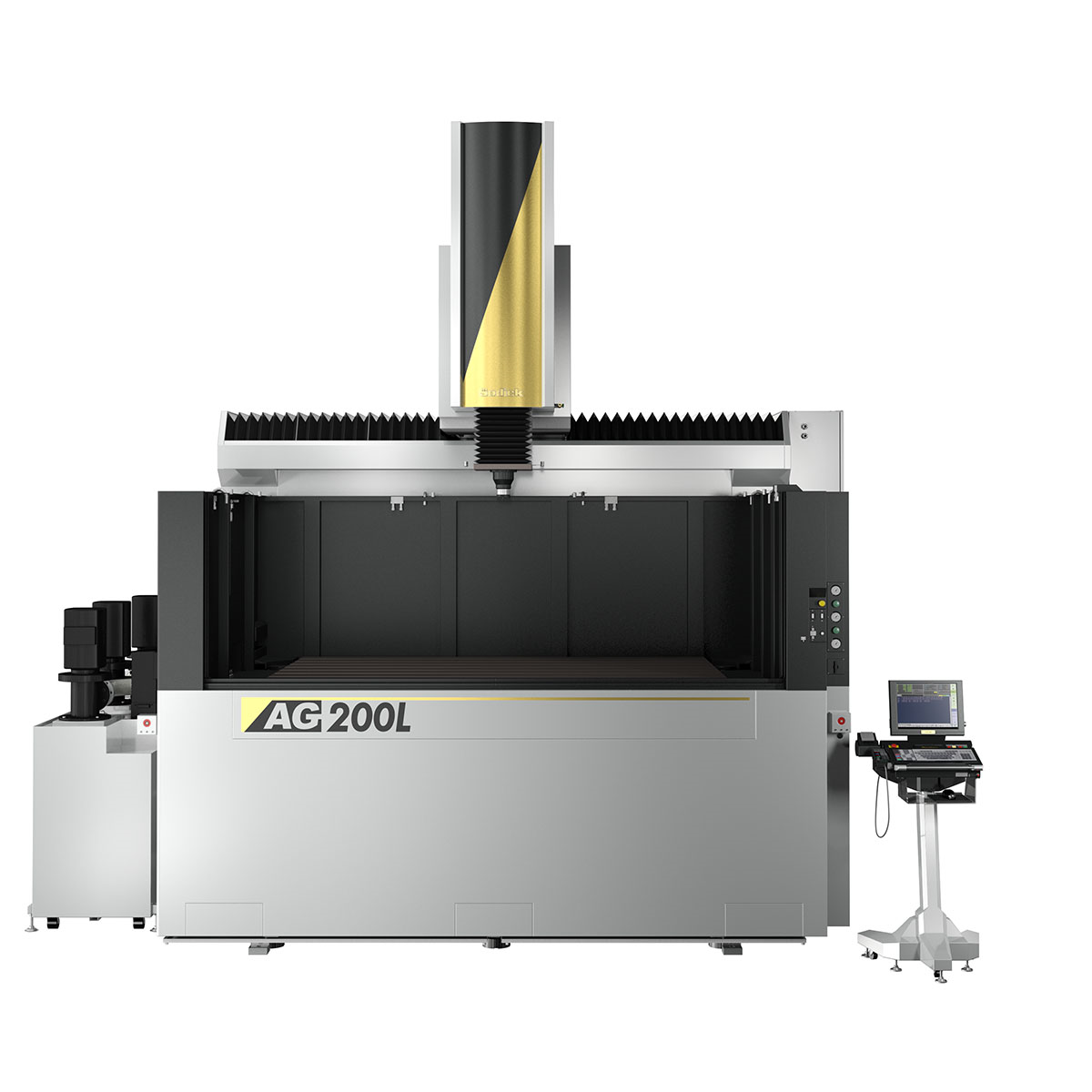

AG200L

Linear Motor Drive High Speed & High Precision Die-Sinker EDM

Best selling Die-sinker EDM which realizes high-speed and high-performance by screw-less drive and arc-less machining.

คุณสมบัติหลัก

Linear Motor Drive System

Linear motor drive system is the most ideal mechanism which semi-permanently sustains high-speed axis-movements and instantaneous response. With 10-years of history providing linear motor-driven machines.

New Generator

The 5th generation electrical discharge technology has adopted the "Perfect Active Control," enabling simultaneous control of high-speed electrical discharge and axis-movements by using serial communication technology of 1Gbit/sec.

Arc-less & High Quality Surface Finish

The new "Arc-less" electrical discharge system features further improved in machining performance, and ensures great reduction in machining time. Equipped with "SVC" circuit as standard, high-quality surface finishing, satin surface, and mirror surface can be achieved with great ease.

ข้อมูลจำเพาะของผลิตภัณฑ์

| ข้อกำหนดทางเทคนิค | ||

|---|---|---|

| X/Y/Z axis travel (mm) | 2000 x 1200 x 800 | |

| Table dimensions (mm) | 2500 x 1550 | |

| Worktank dimensions (mm) | 3000 x 1800 x 1150 | |

| Dielectric level (min ~ max, mm) | 520 ~ 950 | |

| Max. workpiece weight (kg) | 10000 | |

| Max. electrode weight (kg) | 100 | |

| Distance from floor to table top (mm) | 1440 | |

| Machine tool dimensions (W x D x H, mm,) | 4770 x 5220 x 4605 (Incl. power supply and dielectric tank) |

|

| Step resolution (mm) | 0.0001 | |

| Machine weight (kg) | 19000 | |

| Controlled axis | 4 | |

| Air pressure | 0.65 (Automatic Clamping chuck, MPa) |

|

| External dimensions Main- (W x D x H, mm) Sub- |

3700 x 900 x 2300 910 x 4500 x 1800 |

|

| Empty weight (kg) | 950 (main) + 850 (sub) | |

| Dielectric fluid | Oil | |

| Capacity (l) | 7000 | |

| Filtration method | 6 replaceable paper filters (MF-2400) | |

AQ15L

Linear Motor Drive Large Size Die Sinker EDM

Large-Capacity Die-Sinker EDM with direct-drive system improves production efficiency of large dies for automotive parts and large flat panels.

คุณสมบัติหลัก

Direct-drive

Sodick's direct-drive system employs linear motors and linear scales, resulting in excellent positioning accuracy with maximum acceleration of 1.2G, made possible by high speed servo-jump. Work set-up is simple and expert-level skills are not required, providing a highly user-friendly operation environment.

Unique machine structure

The workpiece set-up table is completely separated from the drive system, thereby achieving mechanical construction that is completely unaffected by the shifting workpiece weight. In addition, the symmetrical gantry construction reduces mechanical displacement, and provides excellent machining stability.

Increase production efficiency

The extra service stroke allows the machining table workspace to be opened up giving greater access to the area for workpiece set-up. To further increase productivity, automatic tool changer (option) can facilitate continuous hours of automated machining, resulting in improved production efficiency and reliability.

ข้อมูลจำเพาะของผลิตภัณฑ์

| ข้อกำหนดทางเทคนิค | |||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Work table size (W x D) | 1000 x 2000 mm | ||||||||||||||||||||||||||||||||

| Work tank inner dimensions (W x D x H) | 1400 x 2590 x 800mm | ||||||||||||||||||||||||||||||||

| Work tank fluid level (from table top) | 400 - 750 mm | ||||||||||||||||||||||||||||||||

| Work tank capacity | 3100 liter | ||||||||||||||||||||||||||||||||

| X axis stroke | 900 mm | ||||||||||||||||||||||||||||||||

| Y axis stroke | 1500 (+500) mm | ||||||||||||||||||||||||||||||||

| Z axis stroke | 600 mm | ||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

| Max. suspended weight | 100 kg | ||||||||||||||||||||||||||||||||

| Max. weight of workpiece | 1000 mm | ||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

| Distance from Floor to Table Top | 1000 mm | ||||||||||||||||||||||||||||||||

| Machine Tool Dimensions (W x D x H) | 3050 x 5295 x 4220 mm (Includes a Power Supply and Dielectric Tank) |

||||||||||||||||||||||||||||||||

| Machine Tool Weight | 18000kg (includes power supply unit) | ||||||||||||||||||||||||||||||||

| Air Pressure | 0.65 MPa*1 | ||||||||||||||||||||||||||||||||

| Air Flow | 100NL/min | ||||||||||||||||||||||||||||||||

| Total Power Input | 3-phase 50/60 Hz 24.5 kVA (includes an optional fluid cooling unit) |

||||||||||||||||||||||||||||||||

| External dimensions (W x D x H) | 3050 x 2050 x 2550 mm | ||||||||||||||||||||||||||||||||

| Weight (when empty) | 2200 kg | ||||||||||||||||||||||||||||||||

| Machining fluid | Oil | ||||||||||||||||||||||||||||||||

| Capacity | 4500 liter | ||||||||||||||||||||||||||||||||

| Filteration method | Replaceable paper filter | ||||||||||||||||||||||||||||||||

| Max. machining current | 80 A | ||||||||||||||||||||||||||||||||

| EDM power supply | Optimum Pulse Control TMM Power Supply contains SVC, ACS, and other circuits (Fine IP) |

||||||||||||||||||||||||||||||||

| Power requirement | 200/220 V 50/60 Hz | ||||||||||||||||||||||||||||||||

| NC unit | Multi-tasking OS, Si-LINK (Perfect active control) method |

||||||||||||||||||||||||||||||||

| User memory capacity | Editing: 100,000 blocks, Saving: 30 MB | ||||||||||||||||||||||||||||||||

| Memory device | CF card, external memory | ||||||||||||||||||||||||||||||||

| Input format | Touch panel, keyboard, mouse, external memory, LAN | ||||||||||||||||||||||||||||||||

| Display type | 15 inch TFT-LCD | ||||||||||||||||||||||||||||||||

| Character set | Alphanumeric and symbols | ||||||||||||||||||||||||||||||||

| Keyboard | Standard 101-key, function keys | ||||||||||||||||||||||||||||||||

| Remote controller (optional) | Jog, OFF, ACK, ENT, HALT, clamp/unclamp, etc | ||||||||||||||||||||||||||||||||

| Positioning command | Incremental and absolute | ||||||||||||||||||||||||||||||||

| Max. input command | ±999999.999/±99999.9999/±9999.99999 (switchable) | ||||||||||||||||||||||||||||||||

| Machining conditions storage capacity | 1000 conditions (C000 to C999) | ||||||||||||||||||||||||||||||||

| Offset settings storage capacity | 1000 conditions (H000 to H999) | ||||||||||||||||||||||||||||||||

| Program sequence number assignment | N000000000 to N999999999 | ||||||||||||||||||||||||||||||||

| Number of sub-program nesting operations | 50 | ||||||||||||||||||||||||||||||||

| Number of Q command nesting operations | 7 | ||||||||||||||||||||||||||||||||

| Number of coordinates | 60 | ||||||||||||||||||||||||||||||||

| Simultaneous control axes | Max. 4 axes (LP10: max. 6/8 axes) | ||||||||||||||||||||||||||||||||

| Min. input command | 0.1 µm | ||||||||||||||||||||||||||||||||

| Min. drive unit | 0.1 µm | ||||||||||||||||||||||||||||||||

| AJC speed | X, Y axis : Max. 10 m/min, Z axis : 36 m/min | ||||||||||||||||||||||||||||||||

| Max. feed rate | X, Y, Z axis : 6 m/min | ||||||||||||||||||||||||||||||||

| Position detection | Full closed loop (linear scale) | ||||||||||||||||||||||||||||||||

| Drive mechanism | Linear motor | ||||||||||||||||||||||||||||||||

| Compensations | Pitch error compensation,plane pitch error compensation, torque compensation for each axis |

||||||||||||||||||||||||||||||||

| Editing | Editing during machining, multi-editing of two files on one screen |

||||||||||||||||||||||||||||||||

| Graphics | XY, YZ, ZX plane, graphics drawing during

machining, background graphics drawing LORAN shape drawing, discharge graph, etc. |

||||||||||||||||||||||||||||||||

| Note: A linear motor cooling unit is standard fitment. *1 If the specified air pressure cannot be obtained, please install a pressure boosting valve (optional). |

|||||||||||||||||||||||||||||||||

AQ20L

Linear Motor Drive Die-sinker EDM

Large-Capacity Die-Sinker EDM with direct-drive system improves production efficiency of large dies for automotive parts and large flat panels.

คุณสมบัติหลัก

Direct-drive

Sodick's direct-drive system employs linear motors and linear scales, resulting in excellent positioning accuracy with maximum acceleration of 1.2G, made possible by high speed servo-jump. Work set-up is simple and expert-level skills are not required, providing a highly user-friendly operation environment.

Unique machine structure

The workpiece set-up table is completely separated from the drive system, thereby achieving mechanical construction that is completely unaffected by the shifting workpiece weight. In addition, the symmetrical gantry construction reduces mechanical displacement, and provides excellent machining stability.

Increase production efficiency

The extra service stroke allows the machining table workspace to be opened up giving greater access to the area for workpiece set-up. To further increase productivity, automatic tool changer (option) can facilitate continuous hours of automated machining, resulting in improved production efficiency and reliability.

ข้อมูลจำเพาะของผลิตภัณฑ์

| ข้อกำหนดทางเทคนิค | |||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Work table size (W x D) | 1500 x 2000 mm | ||||||||||||||||||||||||||||||||

| Work tank inner dimensions (W x D x H) | 1900 x 2590 x 800 mm | ||||||||||||||||||||||||||||||||

| Work tank fluid level (from table top) | 400 - 750 mm | ||||||||||||||||||||||||||||||||

| Work tank capacity | 4000 liter | ||||||||||||||||||||||||||||||||

| X axis stroke | 1200 mm | ||||||||||||||||||||||||||||||||

| Y axis stroke | 2000 mm | ||||||||||||||||||||||||||||||||

| Z axis stroke | 600 mm | ||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

| Max. suspended weight | 100 kg | ||||||||||||||||||||||||||||||||

| Max. weight of workpiece | 1000 mm | ||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

| Distance from Floor to Table Top | 1000 mm | ||||||||||||||||||||||||||||||||

| Machine Tool Dimensions (W x D x H) | 3550 x 5785 x 4220 mm (Includes a Power Supply and Dielectric Tank) |

||||||||||||||||||||||||||||||||

| Machine Tool Weight | 22000kg (includes power supply unit) | ||||||||||||||||||||||||||||||||

| Air Pressure | 0.65 MPa*1 | ||||||||||||||||||||||||||||||||

| Air Flow | 100NL/min | ||||||||||||||||||||||||||||||||

| Total Power Input | 3-phase 50/60 Hz 18 kVA (includes an optional fluid cooling unit) |

||||||||||||||||||||||||||||||||

| External dimensions (W x D x H) | 3050 x 2050 x 2550 mm | ||||||||||||||||||||||||||||||||

| Weight (when empty) | 2200 kg | ||||||||||||||||||||||||||||||||

| Machining fluid | Oil | ||||||||||||||||||||||||||||||||

| Capacity | 4500 liter | ||||||||||||||||||||||||||||||||

| Filteration method | Replaceable paper filter | ||||||||||||||||||||||||||||||||

| Max. machining current | 80 A | ||||||||||||||||||||||||||||||||

| EDM power supply | Optimum Pulse Control TMM Power Supply contains SVC, ACS, and other circuits (Fine IP) |

||||||||||||||||||||||||||||||||

| Power requirement | 200/220 V 50/60 Hz | ||||||||||||||||||||||||||||||||

| NC unit | Multi-tasking OS, Si-LINK (Perfect active control) method |

||||||||||||||||||||||||||||||||

| User memory capacity | Editing: 100,000 blocks, Saving: 30 MB | ||||||||||||||||||||||||||||||||

| Memory device | CF card, external memory | ||||||||||||||||||||||||||||||||

| Input format | Touch panel, keyboard, mouse, external memory, LAN | ||||||||||||||||||||||||||||||||

| Display type | 15 inch TFT-LCD | ||||||||||||||||||||||||||||||||

| Character set | Alphanumeric and symbols | ||||||||||||||||||||||||||||||||

| Keyboard | Standard 101-key, function keys | ||||||||||||||||||||||||||||||||

| Remote controller (optional) | Jog, OFF, ACK, ENT, HALT, clamp/unclamp, etc | ||||||||||||||||||||||||||||||||

| Positioning command | Incremental and absolute | ||||||||||||||||||||||||||||||||

| Max. input command | ±999999.999/±99999.9999/±9999.99999 (switchable) | ||||||||||||||||||||||||||||||||

| Machining conditions storage capacity | 1000 conditions (C000 to C999) | ||||||||||||||||||||||||||||||||

| Offset settings storage capacity | 1000 conditions (H000 to H999) | ||||||||||||||||||||||||||||||||

| Program sequence number assignment | N000000000 to N999999999 | ||||||||||||||||||||||||||||||||

| Number of sub-program nesting operations | 50 | ||||||||||||||||||||||||||||||||

| Number of Q command nesting operations | 7 | ||||||||||||||||||||||||||||||||

| Number of coordinates | 60 | ||||||||||||||||||||||||||||||||

| Simultaneous control axes | Max. 4 axes (LP10: max. 6/8 axes) | ||||||||||||||||||||||||||||||||

| Min. input command | 0.1 µm | ||||||||||||||||||||||||||||||||

| Min. drive unit | 0.1 µm | ||||||||||||||||||||||||||||||||

| AJC speed | X, Y axis : Max. 10 m/min, Z axis : 36 m/min | ||||||||||||||||||||||||||||||||

| Max. feed rate | X, Y, Z axis : 6 m/min | ||||||||||||||||||||||||||||||||

| Position detection | Full closed loop (linear scale) | ||||||||||||||||||||||||||||||||

| Drive mechanism | Linear motor | ||||||||||||||||||||||||||||||||

| Compensations | Pitch error compensation,plane pitch error compensation, torque compensation for each axis |

||||||||||||||||||||||||||||||||

| Editing | Editing during machining, multi-editing of two files on one screen |

||||||||||||||||||||||||||||||||

| Graphics | XY, YZ, ZX plane, graphics drawing during

machining, background graphics drawing LORAN shape drawing, discharge graph, etc. |

||||||||||||||||||||||||||||||||

| Note: A linear motor cooling unit is standard fitment. *1 If the specified air pressure cannot be

obtained, please install a pressure boosting valve (optional). |

|||||||||||||||||||||||||||||||||

AD35L

Linear Motor Drive Die-sinker EDM

High Speed and High Performance 3 Axes Linear Motor Drive EDM The screw-less drive, which uses a linear motor and linear scale, is the ideal drive method which maintains high-speed and high response performance semi-permanently. In addition, the AD35L employs the latest technology in highly rigid construction.

คุณสมบัติหลัก

Screw-Less drive + highly rigid construction

The screw-less drive, which uses a linear motor and liner scale, is the ideal drive method which maintenance high-speed and high response performance semi-permanently. In addition, the AD Series employs the lasted technology in highly rigid construction.

New NC Unit with "TMM3" Discharge Power Supply

The AD Sieries features Sodick's latest "LN" NC unit equipped with the new "TMM3" discharge power supply, capable of high-speed, high precision and high-efficiency machining.It is equipped with "LN Professional", Automatic programming funtion, as standrad.

Arc-less & High Quality Surface Finish

The new "Arc-less" electrical discharge system features further improved in machining performance, and ensures great reduction in machining time. Equipped with "SVC" circuit as standard, high-quality surface finishing, satin surface, and mirror surface can be achieved with great ease.

ข้อมูลจำเพาะของผลิตภัณฑ์

| ข้อกำหนดทางเทคนิค | |||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Work table size (W x D) | 600 x 400 mm | ||||||||||||||||||||||||||||||||

| Work tank inner dimensions (W x D x H) | 975 x 555 x 350 mm | ||||||||||||||||||||||||||||||||

| Work tank fluid level (Min. to Max.) | 170 - 300 mm | ||||||||||||||||||||||||||||||||

| Work tank capacity | 180 liter | ||||||||||||||||||||||||||||||||

| X axis stroke | 350 mm | ||||||||||||||||||||||||||||||||

| Y axis stroke | 250 mm | ||||||||||||||||||||||||||||||||

| Z axis stroke | 270 mm | ||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

| Max. weight of workpiece | 550 kg | ||||||||||||||||||||||||||||||||

| Max. thrust*2 | 50 kg | ||||||||||||||||||||||||||||||||

| Distance between electrode and table top*3 | 217 - 487 mm | ||||||||||||||||||||||||||||||||

| Distance from floor to table top | 810 mm | ||||||||||||||||||||||||||||||||

| Machine tool dimensions (W x D x H) | 1895 x 1955 x 235 0mm (includes a power supply and dielectric tank) |

||||||||||||||||||||||||||||||||

| Machine tool weight | 3200 kg (includes a power supply and dielectric tank) | ||||||||||||||||||||||||||||||||

| Total power input | 3 phase 50/60 Hz 10kVA | ||||||||||||||||||||||||||||||||

| Air pressure | 0.65MPa | ||||||||||||||||||||||||||||||||

| Air flow | 100NL /min | ||||||||||||||||||||||||||||||||

| External dimensions ( W × D × H ) | 800 × 1705 × 2050 | ||||||||||||||||||||||||||||||||

| Dielectric | oil | ||||||||||||||||||||||||||||||||

| Capacity | 400 Liter | ||||||||||||||||||||||||||||||||

| Filteration method | Replaceable paper filter | ||||||||||||||||||||||||||||||||

| Max. machining current | 40A | ||||||||||||||||||||||||||||||||

| EDM section power supply | Optimum pulse control TMM3 power supply (contains an "Arc-less", SVC circuit, ACS circuit |

||||||||||||||||||||||||||||||||

| Power requirement | 200/220 V 50/60 Hz | ||||||||||||||||||||||||||||||||

| NC unit | Multi-tasking OS, SI-LINK (Perfect active control) | ||||||||||||||||||||||||||||||||

| User's memory capacity | Editing: 100,000 blocks Saving: 30 MB | ||||||||||||||||||||||||||||||||

| Memory device | CF card, external memory | ||||||||||||||||||||||||||||||||

| Input format | External memory Touch panel, keyboard | ||||||||||||||||||||||||||||||||

| Display type | 15 inch TFT-LCD (XGA) | ||||||||||||||||||||||||||||||||

| Character set | Alphanumeric and symbols | ||||||||||||||||||||||||||||||||

| Keyboard | Standard 101-key, function key | ||||||||||||||||||||||||||||||||

| Remote controller | Jog, OFF, ACK, ENT, HALT, Clamp/Unclamping, etc. | ||||||||||||||||||||||||||||||||

| Positioning command | Incremental and absolute | ||||||||||||||||||||||||||||||||

| Max. input command | ±999999.999/±99999.9999/±9999.99999 (switchable) |

||||||||||||||||||||||||||||||||

| Machining conditions storage capacity | 1000 conditions | ||||||||||||||||||||||||||||||||

| Offset settings storage capacity | 1000 conditions (H000 to H999) | ||||||||||||||||||||||||||||||||

| Program sequence number assignment | N000000000 to N999999999 | ||||||||||||||||||||||||||||||||

| Number of sub-program nesting operations | 50 | ||||||||||||||||||||||||||||||||

| Number of Q command nesting operations | 7 | ||||||||||||||||||||||||||||||||

| Number of coordinates | 60 | ||||||||||||||||||||||||||||||||

| Simultaneous control axes | Max. 4 axes | ||||||||||||||||||||||||||||||||

| Min. input command | 0.1 μm | ||||||||||||||||||||||||||||||||

| Min. drive unit | 0.1 μm | ||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

| Max. feed rate | 3 m/min (X, Y, Z axis) | ||||||||||||||||||||||||||||||||

| Position detection | Full closed loop (linear scale) | ||||||||||||||||||||||||||||||||

| Drive mechanism | Linear motor and rotary motor | ||||||||||||||||||||||||||||||||

| Compensations | Pitch, Backlash and Torque compensation (Separated to each axes) |

||||||||||||||||||||||||||||||||

| Editing | Editing during machining, 2-files simultaneous display, Backgroud editing |

||||||||||||||||||||||||||||||||

| Graphics | XY, YZ, ZX plane, graphics drawing during machining, background graphics drawing, LORAN shape drawing, discharge graph, etc. |

||||||||||||||||||||||||||||||||

AD55L

Linear Motor Drive Die-sinker EDM

High Speed and High Performance 3 Axes Linear Motor Drive EDM The screw-less drive, which uses a linear motor and linear scale, is the ideal drive method which maintains high-speed and high response performance semi-permanently. In addition, the AD35L employs the latest technology in highly rigid construction.

คุณสมบัติหลัก

Screw-Less drive + highly rigid construction

The screw-less drive, which uses a linear motor and liner scale, is the ideal drive method which maintenance high-speed and high response performance semi-permanently. In addition, the AD Series employs the lasted technology in highly rigid construction.

New NC Unit with "TMM3" Discharge Power Supply

The AD Sieries features Sodick's latest "LN" NC unit equipped with the new "TMM3" discharge power supply, capable of high-speed, high precision and high-efficiency machining.It is equipped with "LN Professional", Automatic programming funtion, as standrad.

Arc-less & High Quality Surface Finish

The new "Arc-less" electrical discharge system features further improved in machining performance, and ensures great reduction in machining time. Equipped with "SVC" circuit as standard, high-quality surface finishing, satin surface, and mirror surface can be achieved with great ease.

ข้อมูลจำเพาะของผลิตภัณฑ์

| ข้อกำหนดทางเทคนิค | |||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Work table size (W x D) | 750 x 550 mm | ||||||||||||||||||||||||||||||||

| Work tank inner dimensions (W x D x H) | 1200 x 800 x 500 mm | ||||||||||||||||||||||||||||||||

| Work tank fluid level (Min. to Max.) | 170 - 450 mm | ||||||||||||||||||||||||||||||||

| Work tank capacity | 470 liter | ||||||||||||||||||||||||||||||||

| X axis stroke | 600 mm | ||||||||||||||||||||||||||||||||

| Y axis stroke | 400 mm | ||||||||||||||||||||||||||||||||

| Z axis stroke | 400 mm | ||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

| Max. weight of workpiece | 100 kg | ||||||||||||||||||||||||||||||||

| Max. thrust*2 | 50 kg | ||||||||||||||||||||||||||||||||

| Distance between electrode and table top*3 | 240 - 640 mm | ||||||||||||||||||||||||||||||||

| Distance from floor to table top | 900 mm | ||||||||||||||||||||||||||||||||

| Machine tool dimensions (W x D x H) | 2335 x 2325 x 2720 mm (includes a power supply and dielectric tank) |

||||||||||||||||||||||||||||||||

| Machine tool weight | 4600kg (includes a power supply and dielectric tank) | ||||||||||||||||||||||||||||||||

| Total power input | 3 phase 50/60 Hz 10kVA | ||||||||||||||||||||||||||||||||

| Air pressure | 0.65MPa | ||||||||||||||||||||||||||||||||

| Air flow | 100NL /min | ||||||||||||||||||||||||||||||||

| External dimensions ( W × D × H ) | 1050 × 2005 × 2140 | ||||||||||||||||||||||||||||||||

| Dielectric | oil | ||||||||||||||||||||||||||||||||

| Capacity | 800 Liter | ||||||||||||||||||||||||||||||||

| Filteration method | 2 Replaceable paper filter | ||||||||||||||||||||||||||||||||

| Max. machining current | 40A | ||||||||||||||||||||||||||||||||

| EDM section power supply | Optimum pulse control TMM3 power supply (contains an "Arc-less", SVC circuit, ACS circuit |

||||||||||||||||||||||||||||||||

| Power requirement | 200/220 V 50/60 Hz | ||||||||||||||||||||||||||||||||

| NC unit | Multi-tasking OS, SI-LINK (Perfect active control) | ||||||||||||||||||||||||||||||||

| User's memory capacity | Editing: 100,000 blocks Saving: 30 MB | ||||||||||||||||||||||||||||||||

| Memory device | CF card, external memory | ||||||||||||||||||||||||||||||||

| Input format | External memory Touch panel, keyboard | ||||||||||||||||||||||||||||||||

| Display type | 15 inch TFT-LCD (XGA) | ||||||||||||||||||||||||||||||||

| Character set | Alphanumeric and symbols | ||||||||||||||||||||||||||||||||

| Keyboard | Standard 101-key, function key | ||||||||||||||||||||||||||||||||

| Remote controller | Jog, OFF, ACK, ENT, HALT, Clamp/Unclamping, etc. | ||||||||||||||||||||||||||||||||

| Positioning command | Incremental and absolute | ||||||||||||||||||||||||||||||||

| Max. input command | ±999999.999/±99999.9999/±9999.99999 (switchable) |

||||||||||||||||||||||||||||||||

| Machining conditions storage capacity | 1000 conditions | ||||||||||||||||||||||||||||||||

| Offset settings storage capacity | 1000 conditions (H000 to H999) | ||||||||||||||||||||||||||||||||

| Program sequence number assignment | N000000000 to N999999999 | ||||||||||||||||||||||||||||||||

| Number of sub-program nesting operations | 50 | ||||||||||||||||||||||||||||||||

| Number of Q command nesting operations | 7 | ||||||||||||||||||||||||||||||||

| Number of coordinates | 60 | ||||||||||||||||||||||||||||||||

| Simultaneous control axes | Max. 4 axes | ||||||||||||||||||||||||||||||||

| Min. input command | 0.1 μm | ||||||||||||||||||||||||||||||||

| Min. drive unit | 0.1 μm | ||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

| Max. feed rate | 3 m/min (X, Y, Z axis) | ||||||||||||||||||||||||||||||||

| Position detection | Full closed loop (linear scale) | ||||||||||||||||||||||||||||||||

| Drive mechanism | Linear motor and rotary motor | ||||||||||||||||||||||||||||||||

| Compensations | Pitch, Backlash and Torque compensation (Separated to each axes) |

||||||||||||||||||||||||||||||||

| Editing | Editing during machining, 2-files simultaneous display, Backgroud editing |

||||||||||||||||||||||||||||||||

| Graphics | XY, YZ, ZX plane, graphics drawing during machining, background graphics drawing, LORAN shape drawing, discharge graph, etc. |

||||||||||||||||||||||||||||||||

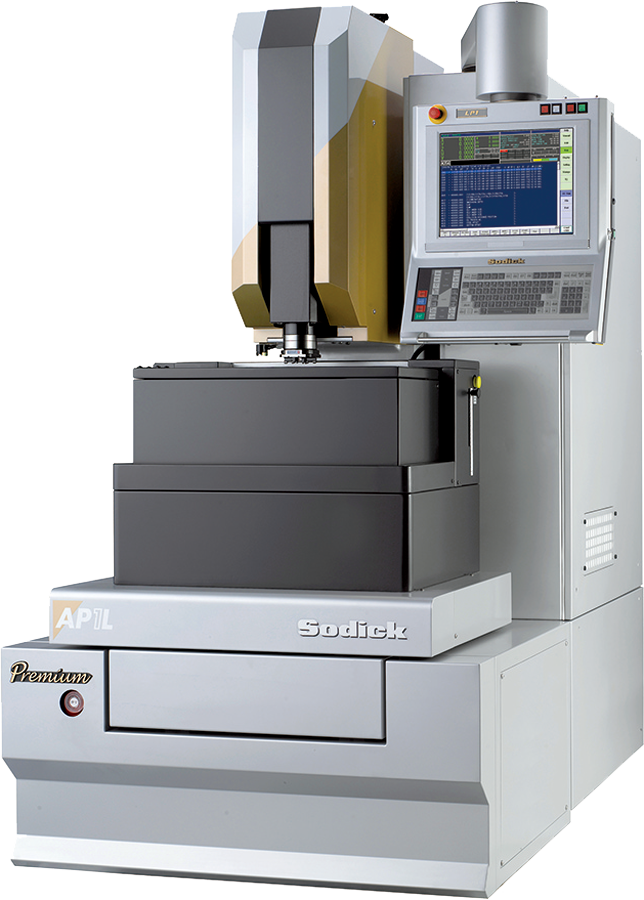

AP1L

Premium High End EDM Machine

Responding to the need for a higher level of machining accuracy, Sodick's AP1L Premium offers solutions to ultra precision machining requirements based on achieved superiority in mini and microscopic machining. production is improved through advanced functions for automation and labour saving operation. Revolutionary technology is needed for electrode dressing to support ultra precision high speed machining of hard and difficult materials in order to achieve manufacturing capability of mini and micro moulds.

คุณสมบัติหลัก

The screw-less drive, which uses a linear motor and linear scale, is the ideal drive method which maintains high-speed and high response performance semi-permanently. In addition, the AP1L employs the latest technology in highly rigid construction, small/precision head, and so on.

High-speed, high quality finishing “SVC” circuit

The “SVC” circuit increases the machining speed in finishing compared to our previous model, and supplies a uniform discharge pulse between the electrodes. The optimum surface roughness over the machining area is greatly improved, realizing a high quality pear-skin or mirror finish

Three-sided automated vertical slide machining tank

The three-sided automated vertical slide machining tank facilitates setup work for super-precision machining. It also enables an optimum cost to be configured when a robot is adopted for automation and labor saving.

ข้อมูลจำเพาะของผลิตภัณฑ์

| ข้อกำหนดทางเทคนิค | |

|---|---|

| Ceramic table dimensions | 360 x 220 mm |

| Worktank dimensions (W x D x H) | 503 x 349 x 250 mm |

| Dielectric level (min~max, mm) | 80 ~ 200 mm |

| X-/Y-/Z- axis travel | 200 x 120 x 200 mm |

| Step resolution | 0.0001 mm |

| Max. electrode weight | 5 kg |

| Max. workpiece weight | 25 kg |

| Distance from floor to table top | 940 mm |

| Machine tool dimensions (W x D x H) Incl. | 1360 x 1920 x 2030 mm power supply and dielectric tank |

| Machine installation space (W×D) | 2000 x 2280 mm (including maintenance space) |

| Machine weight | 3100 kg |

| Controlled axis | 4 |

| Air pressure | 0.65 MPa |

| External dimensions (W x D x H) | 1095 x 435 x 785 |

| Dielectric fluid | Oil |

| Capacity (l) | 120 |

| Filtration method | Replaceable paper filter (MF-1530P) |

| Max. machining current | 20A (AP1L = 10A) |

| Discharging power supply unit | Optimum pulse control for TMM 3 power supply (SGF Plus, SVC circuit) |

| Power requirement | 200/220 V 50/60 Hz |

| CNC unit | Multi-tasking OS, KSMC-LINK system |

| User's memory capacity | Editing: 100,000 block Saving: 30 MB |

| Memory device | CF card, External memory |

| Input format | External memory, Touch panel, Keyboard, |

| Display type | 15" TFT-LCD (XGA) |

| Character set | Alphanumeric and symbols |

| Keyboard | Standard 101-key, Function key |

| Remote Controller (Standard) | Standard jog (switchable), Assist A0 to A3, Clamp / unclamp,etc. |

| Positioning command | Incremental and absolute |

| Max. input command | ±999999.999 / ±99999.9999 / ±999.99999 (switchable) |

| Machining conditions storage capacity | 1000 conditions |

| Offset settings storage capacity | 1000 conditions (H000 to H999) |

| Programme sequence number assignment | N000000000 to N999999999 |

| Sub-programme nesting levels | 50 |

| Q command nesting levels | 8 |

| Number of co-ordinates | 60 |

| Simultaneous control axes | Max 4 axes (Max 6 axes, 8 axes/LN20) |

| Min. input command | 0.1 µm |

| Min. drive unit | 0.1 µm |

| AJC speed | X, Y axis Max. 10 m/min , Z axis Max. 36 m/min |

| Jog feed rate | X, Y, Z axis Max. 6 m/min |

| Control system | Full closed loop (Linear scales) |

| Drive mechanism | Linear motor |

| Compensation | Separated to each axes/ Backlash and Torque compensation |

| Editing | 2-screen simultaneous display, Background editing |

| Graphics XY plane, XY-YZ plane, 3D, Background graphics, Orbit shape graphics, Discharge graph, etc. |

|

| The dielectric chillers on Sodick machines contain either

fluorinated greenhouse gas R410A or R407C. *1 Please select the appropriate clamping chuck for your system. · Selection: LN2/LN20. Please consult sales representatives for more details. · Specifications are subject to change without prior notice due to continual research and development. |

|