IMMIMM

GL30A

V-LINE® /Injection Molding Machine/for High Value-Added Products

V-LINE®'s global standard model contributes to high value-added molding in extensive fields, including precision, electronics, optics and medical equipments.

Main Features

Excellent Plasticization & Injection Performance

Equipped with a highly stable and highly reliable plasticization and injection unit realized by Sodick's original V-LINE® which contributes to accurate and highly repeatable resin injection, and a hydraulic accumulator mechanism that enables high speed injection with dynamic responsiveness at a high level

Original Mold Open/Close & Clamping Mechanism

Adopts both a mold open/close mechanism which realizes accurate position control by an elect ronic system, and a mold clamping mechanism that reproduces an accurate mold clamping force by a hydraul ic sys tem. Equipped with a direct pres sure mold clamping system which utilizes the merits of the electro-hydraulic hybrid system to the utmost.

Total Servo Drive

Further improved energy saving performance by the use of an electric servo motor for the hydraulic pump drive, in addition to the electric servo motor drive for the mold open/ close mechanism and ejection mechanism.

Product Specifications

| Technical Specifications | |

|---|---|

| Max. clamping force (kN) | 294[392] *1 |

| Tie bar distance W x L (mm) | 310 x 310 |

| Platen Dimensions W x L (mm) | 440 x 440 |

| Open daylight (Min. mold thickness + Max. stroke) (mm) | 550 |

| Min. mold thickness/Max. mold thickness (mm) | 150/360 |

| Max. injection pressure (MPa) | 288 | 262 | 260 |

| Max. injection speed (mm/s) | 500 |

| Machine size L x W x H (mm) | 3150 x 1030 x 1679 |

| Machine weight (kg) | 2000 |

| Drive system | Electric Hybrid |

GL60A

V-LINE® /Injection Molding Machine/for High Value-Added Products

V-LINE®'s global standard model contributes to high value-added molding in extensive fields, including precision, electronics, optics and medical equipments.

Main Features

Excellent Plasticization & Injection Performance

Equipped with a highly stable and highly reliable plasticization and injection unit realized by Sodick's original V-LINE® which contributes to accurate and highly repeatable resin injection, and a hydraulic accumulator mechanism that enables high speed injection with dynamic responsiveness at a high level

Original Mold Open/Close & Clamping Mechanism

Adopts both a mold open/close mechanism which realizes accurate position control by an elect ronic system, and a mold clamping mechanism that reproduces an accurate mold clamping force by a hydraul ic sys tem. Equipped with a direct pres sure mold clamping system which utilizes the merits of the electro-hydraulic hybrid system to the utmost.

Total Servo Drive

Further improved energy saving performance by the use of an electric servo motor for the hydraulic pump drive, in addition to the electric servo motor drive for the mold open/ close mechanism and ejection mechanism.

Product Specifications

| Technical Specifications | |

|---|---|

| Max. clamping force (kN) | 588 |

| Tie bar distance W x L (mm) | 360 x 320 |

| Platen Dimensions W x L (mm) | 520 x 460 |

| Open daylight (Min. mold thickness + Max. stroke) (mm) | 650 |

| Min. mold thickness/Max. mold thickness (mm) | 200/390 |

| Max. injection pressure (MPa) | 260 | 240 |

| Max. injection speed (mm/s) | 500 |

| Machine size L x W x H (mm) | 3685 x 1094 x 1679 |

| Machine weight (kg) | 2800 |

| Drive system | Electric Hybrid |

GL100A

V-LINE® /Injection Molding Machine/for High Value-Added Products

V-LINE®'s global standard model contributes to high value-added molding in extensive fields, including precision, electronics, optics and medical equipments.

Main Features

Excellent Plasticization & Injection Performance

Equipped with a highly stable and highly reliable plasticization and injection unit realized by Sodick's original V-LINE® which contributes to accurate and highly repeatable resin injection, and a hydraulic accumulator mechanism that enables high speed injection with dynamic responsiveness at a high level

Original Mold Open/Close & Clamping Mechanism

Adopts both a mold open/close mechanism which realizes accurate position control by an elect ronic system, and a mold clamping mechanism that reproduces an accurate mold clamping force by a hydraul ic sys tem. Equipped with a direct pres sure mold clamping system which utilizes the merits of the electro-hydraulic hybrid system to the utmost.

Total Servo Drive

Further improved energy saving performance by the use of an electric servo motor for the hydraulic pump drive, in addition to the electric servo motor drive for the mold open/ close mechanism and ejection mechanism.

Product Specifications

| Technical Specifications | |

|---|---|

| Max. clamping force (kN) | 980 |

| Tie bar distance W x L (mm) | 460 x 420 |

| Platen Dimensions W x L (mm) | 640 x 610 |

| Open daylight (Min. mold thickness + Max. stroke) (mm) | 800 |

| Min. mold thickness/Max. mold thickness (mm) | 250/550 |

| Max. injection pressure (MPa) | 240 | 220 | |

| Max. injection speed (mm/s) | 500 | 400 | 300 |

| Machine size L x W x H (mm) | 4030 x 1196 x 1792 |

| Machine weight (kg) | 3300 |

| Drive system | Electric Hybrid |

GL150A

V-LINE® /Injection Molding Machine/for High Value-Added Products

V-LINE®'s global standard model contributes to high value-added molding in extensive fields, including precision, electronics, optics and medical equipments.

Main Features

Excellent Plasticization & Injection Performance

Equipped with a highly stable and highly reliable plasticization and injection unit realized by Sodick's original V-LINE® which contributes to accurate and highly repeatable resin injection, and a hydraulic accumulator mechanism that enables high speed injection with dynamic responsiveness at a high level

Original Mold Open/Close & Clamping Mechanism

Adopts both a mold open/close mechanism which realizes accurate position control by an elect ronic system, and a mold clamping mechanism that reproduces an accurate mold clamping force by a hydraul ic sys tem. Equipped with a direct pres sure mold clamping system which utilizes the merits of the electro-hydraulic hybrid system to the utmost.

Total Servo Drive

Further improved energy saving performance by the use of an electric servo motor for the hydraulic pump drive, in addition to the electric servo motor drive for the mold open/ close mechanism and ejection mechanism.

Product Specifications

| Technical Specifications | |

|---|---|

| Max. clamping force (kN) | 1472 |

| Tie bar distance W x L (mm) | 560 x 520 |

| Platen Dimensions W x L (mm) | 720 x 680 |

| Open daylight (Min. mold thickness + Max. stroke) (mm) | 900 |

| Min. mold thickness/Max. mold thickness (mm) | 250/600 |

| Max. injection pressure (MPa) | 240 | 220 | 210 |

| Max. injection speed (mm/s) | 500 | 400 | 300 |

| Machine size L x W x H (mm) | 4400 x 1378 x 1878 |

| Machine weight (kg) | 5100 |

| Drive system | Electric Hybrid |

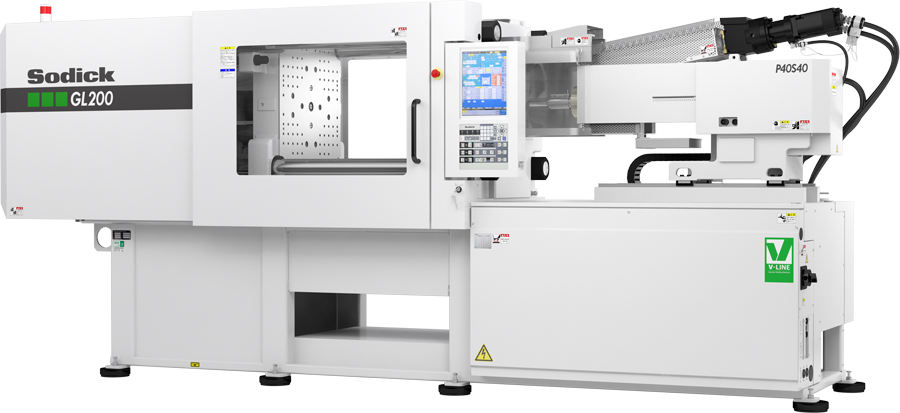

GL200A

V-LINE® /Injection Molding Machine/for High Value-Added Products

V-LINE®'s global standard model contributes to high value-added molding in extensive fields, including precision, electronics, optics and medical equipments.

Main Features

Excellent Plasticization & Injection Performance

Equipped with a highly stable and highly reliable plasticization and injection unit realized by Sodick's original V-LINE® which contributes to accurate and highly repeatable resin injection, and a hydraulic accumulator mechanism that enables high speed injection with dynamic responsiveness at a high level

Original Mold Open/Close & Clamping Mechanism

Adopts both a mold open/close mechanism which realizes accurate position control by an elect ronic system, and a mold clamping mechanism that reproduces an accurate mold clamping force by a hydraul ic sys tem. Equipped with a direct pres sure mold clamping system which utilizes the merits of the electro-hydraulic hybrid system to the utmost.

Total Servo Drive

Further improved energy saving performance by the use of an electric servo motor for the hydraulic pump drive, in addition to the electric servo motor drive for the mold open/ close mechanism and ejection mechanism.

Product Specifications

| Technical Specifications | |

|---|---|

| Max. clamping force (kN) | 1960 |

| Tie bar distance W x L (mm) | 560 x 560 |

| Platen Dimensions W x L (mm) | 680 x 680 |

| Open daylight (Min. mold thickness + Max. stroke) (mm) | 950 |

| Min. mold thickness/Max. mold thickness (mm) | 300/650 |

| Max. injection pressure (MPa) | 240 | 220 | 210 |

| Max. injection speed (mm/s) | 500 | 400 | 300 |

| Machine size L x W x H (mm) | 4505 x 1360 x 1990 |

| Machine weight (kg) | 5900 |

| Drive system | Electric Hybrid |